In the early days of 3D Printing, enthusiasts were limited by the scarcity of materials and the technology's novelty. As the industry evolved, so did the array of filament options, transforming ideas into tangible creations with unprecedented ease. Today, materials like PLA and PETG have become staples in the 3D Printing community, each offering unique properties that cater to various project needs.

From hobbyists crafting intricate models to professionals prototyping complex components, selecting the right filament is crucial. Understanding the differences between PLA and PETG not only enhances the quality of your prints but also opens doors to innovative applications in the ever-growing field of 3D Printing.

Choosing between PLA and PETG is essential for the success of your 3D Printing projects; understanding their distinct properties will help you select the filament that best suits your needs while preparing you for future advancements in the industry.

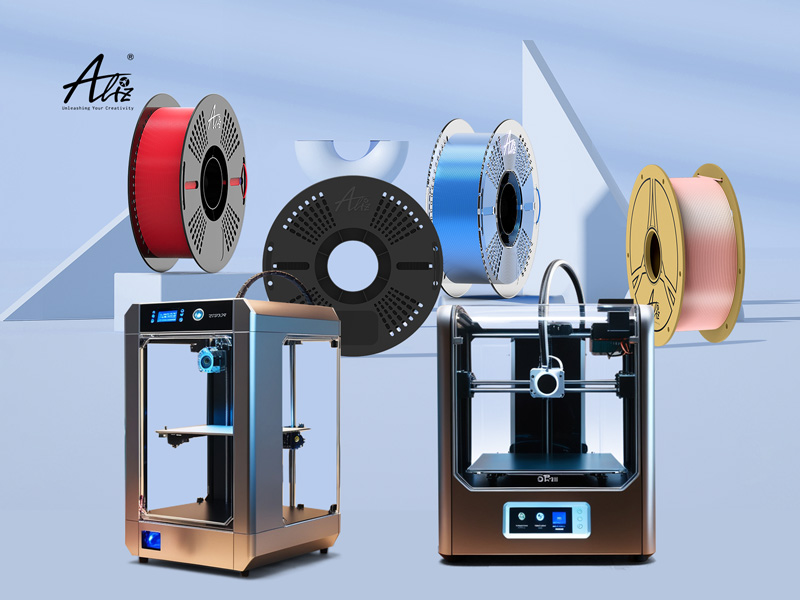

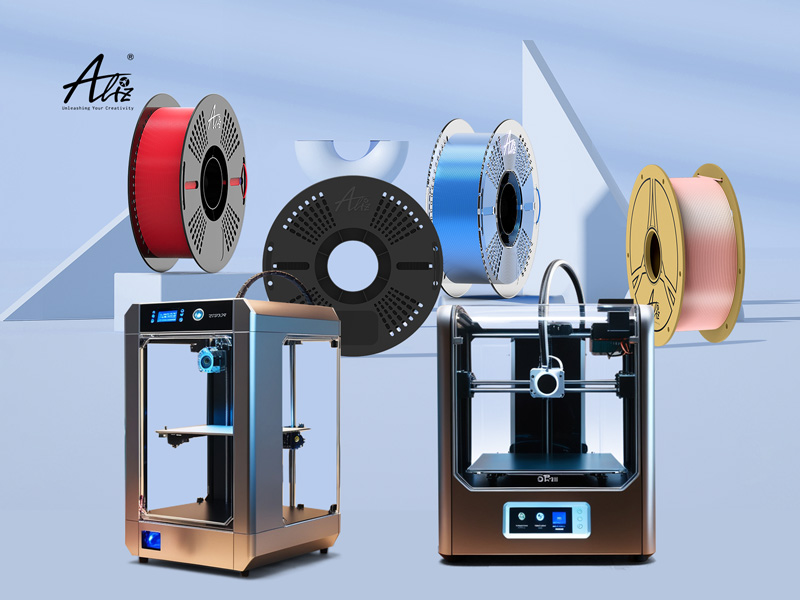

![filament]()

Understanding PLA Filament

Polylactic Acid (PLA) is one of the most popular materials used in desktop 3D Printing. Derived from renewable resources like corn starch or sugarcane, PLA is praised for its environmentally friendly nature. It's biodegradable under commercial composting conditions, making it an appealing choice for those concerned about sustainability.

PLA is known for its ease of use, especially for beginners. It requires lower printing temperatures, typically between 190°C to 220°C, and doesn't necessitate a heated bed, although using one can improve print adhesion. PLA has minimal warping issues, allowing for high-detail prints without the stress of significant thermal contraction.

The material's versatility extends to its wide range of colors and finishes. Manufacturers offer PLA in various shades, translucent options, and even composites infused with wood, marble, or glow-in-the-dark materials. This diversity enables creators to produce visually striking prints suitable for decorative items, toys, and prototypes.

However, PLA has its limitations. It's relatively brittle compared to other materials, making it less ideal for functional parts that require flexibility or impact resistance. PLA also has a lower heat resistance; objects made from it can deform at temperatures above 60°C, which restricts its use in high-temperature environments.

![3D PLA Filament]()

Aliz PLA Basic

We highly recommend Aliz PLA Basic:

Compared to traditional PLA, Aliz PLA Basic improves impact resistance (toughening); High bonding strength (exceptional layer adhesion); Not easy to draw & stringing when printing; (Increased service cycle life: The biodegradable cycle of PLA was delayed). Based on modified PLA, the Material Performance even exceeds that of some brands of PLA+.

![News3-600x500-Aliz-PLA-Basic11]()

![News4-600x500-Aliz-PLA-Basic21]()

Exploring PETG Filament

Polyethylene Terephthalate Glycol-modified (PETG) is a filament that bridges the gap between PLA and more robust materials like ABS. PETG combines the ease of printing associated with PLA and the strength and durability found in ABS. It's a popular choice for those needing more resilient prints without significantly increasing printing difficulty.

PETG prints at higher temperatures, usually between 230°C to 280°C, and benefits from a heated bed set around 70°C to 90°C to prevent warping. It's less prone to shrinkage and layer adhesion issues, resulting in strong and durable prints. PETG's toughness makes it suitable for some mechanical parts, functional prototypes, and items exposed to stress and strain.

A notable feature of PETG is its flexibility. Unlike PLA, which can be brittle, PETG offers a balance of rigidity and flexibility, reducing the likelihood of parts cracking under pressure. Additionally, PETG is more chemically resistant and has a higher temperature tolerance, maintaining its shape up to around 80°C.

PETG is also known for its clarity and glossy finish. It's commonly used in applications where transparency is beneficial, such as light fixtures and protective covers. However, PETG can be more sensitive to moisture absorption, requiring proper storage in airtight containers with desiccants to maintain optimal printing performance.

![PETG Filament]()

Aliz PETG

Aliz PETG has a high transparency (good surface glossiness-bright). Besides, compared to conventional PETG, it has good impact resistance (good toughness). Its printed parts is food contact grade and can be used for a long time.

Quality of Aliz PETG are comparable to Top-Tier Brands (such as eSUN, Polymaker, and KEXCELLED). Currently, we are in the brand promotion stage, offering our products at competitive prices aligned with Second-tier Brands, providing significant value to our customers. Here are Five Main Advantages of Aliz PETG Filament:

(1) High layer viscosity and excellent layer adhesion;

(2) Very accurate colors, perfectly matching the color card of Bambu Lab;

(3) Support high-speed Printing (print with high flowing), allowing Turbo mode throughout the whole printing process, Printing speed up to 500mm/s;

(4) Printed supports are easy to remove;

(5) Excellent layer adhesion strength with minimal stringing.

![企业微信截图_17410684298029]()

![企业微信截图_17410684361293]()

Aliz PETG Metallic

Aliz PETG Metallic Series is a 3D Printing Filament with premium metallic luster, giving printed models a high-end texture and metallic appearance. Meanwhile, Aliz has mature processes and formulations for PETG Metallic Filament, ensuring excellent printing performance without compromising print fluidity due to special effects.The metallic colors allow ordinary parts instantly free from the plastic feeling, which makes the printed parts more superior and refined!

![Aliz PETG Metallic]()

Aliz PETG Translucent

As the new launched range in Aliz PETG, it has the following product features: Semi-transparent appearance; Ultra-long & Superior durability; Seamless and smooth printing process; Least prone to shrinkage and warp; Optimal light transmittance, etc. Besides, Aliz PETG Translucent offers a unique combination of strength and visual appeal, making it an excellent choice for both aesthetic and functional 3D Printing Applications.

![Aliz PETG Translucent]()

![News10 600x500 Aliz PETG Translucent2 News10 600x500 Aliz PETG Translucent2]()

![News11 600x500 Aliz PETG Translucent3 News11 600x500 Aliz PETG Translucent3]()

Comparing PLA and PETG: Which Should You Choose?

Selecting between PLA and PETG depends on your project's specific requirements. If you're focused on ease of printing, intricate details, or environmentally friendly materials, PLA is an excellent choice. Its low printing temperature and minimal warping make it ideal for educational purposes, concept models, and decorative pieces.

For projects that demand durability, impact resistance, and functionality, PETG may be the better option. Its enhanced mechanical properties make it suitable for producing mechanical components, outdoor fixtures, and parts subjected to physical stress. While PETG requires slightly more precise temperature control and bed adhesion, it offers superior performance in demanding applications.

Consider your printer's capabilities as well. PLA's forgiving nature accommodates a wider range of printer setups, while PETG might necessitate a printer with a heated bed and the ability to maintain higher nozzle temperatures. Your comfort level with adjusting print settings and handling different materials should also influence your decision.

Practical Applications and Industry Usage

The choice between PLA and PETG often depends on the intended application. PLA excels in prototyping, educational settings, and artistic projects. Its ability to print at lower temperatures and minimal warping makes it perfect for detailed models and architectural prototypes.

PETG has found its niche in functional parts, particularly those requiring water resistance or food safety compliance. It's commonly used in manufacturing settings for tools, machine parts, and consumer goods. The material's chemical resistance makes it suitable for containers and medical applications.

The adoption patterns in various industries reveal interesting trends. While PLA dominates the hobby and education markets, PETG is increasingly preferred in industrial applications where durability and reliability are paramount. This division is likely to continue as both materials evolve to better serve their respective niches.

Selecting the Right Filament for Your Future Projects

As the options for 3D Printing materials expand, staying informed about filament properties and industry trends becomes increasingly important. Experimenting with different materials can enhance your understanding of 3D Printing and inspire innovative applications.

When planning your projects, consider not only the immediate requirements but also how new materials could offer improved performance or open new possibilities. Keep an eye on industry news, participate in maker communities, and don't hesitate to test new filaments as they become available.

Ensuring that your printer is compatible with various materials and being willing to adjust settings will allow you to take full advantage of cutting-edge filaments. Embracing the evolution of 3D Printing materials positions you to leverage the technology's full potential.

Conclusion

In the rapidly advancing world of 3D Printing, material selection plays a pivotal role in the success and functionality of your projects. By understanding the differences between PLA and PETG, you can make informed decisions that align with your project's needs and your capabilities as a printer operator.

Ultimately, the choice of filament is more than just a technical decision; it's an opportunity to explore, innovate, and push the boundaries of what's possible with 3D Printing. By considering both current options and future advancements, you position yourself to make the most of this transformative technology.

![3D Printing filament]()

FAQ

Q: Can I print PETG on a 3D Printer without a heated bed?

A: While a heated bed improves adhesion for PETG, you can print without one by using adhesion aids like glue sticks or blue painter's tape, though results may vary.

Q: Is PLA safe for printing items that come into contact with food?

A: PLA is generally considered food-safe, but additives and colorants in the filament may not be, so it's important to check the manufacturer's specifications.

Q: How does moisture affect my filament, and what can I do about it?

A: Filaments like PETG absorb moisture, leading to print defects; storing them in airtight containers with desiccants helps maintain quality.

Q: Can I recycle or reuse my 3D Printing Filament scraps?

A: Some companies offer recycling programs, and filament extruders are available to recycle scraps into new filament, promoting sustainability.

Q: What should I consider when trying out new filaments like PPS CF?

A: Check compatibility with your printer, be prepared to adjust settings, and follow manufacturer guidelines to achieve optimal results with new materials.